Predictive maintenance of rolling stocks and railway infrastructures

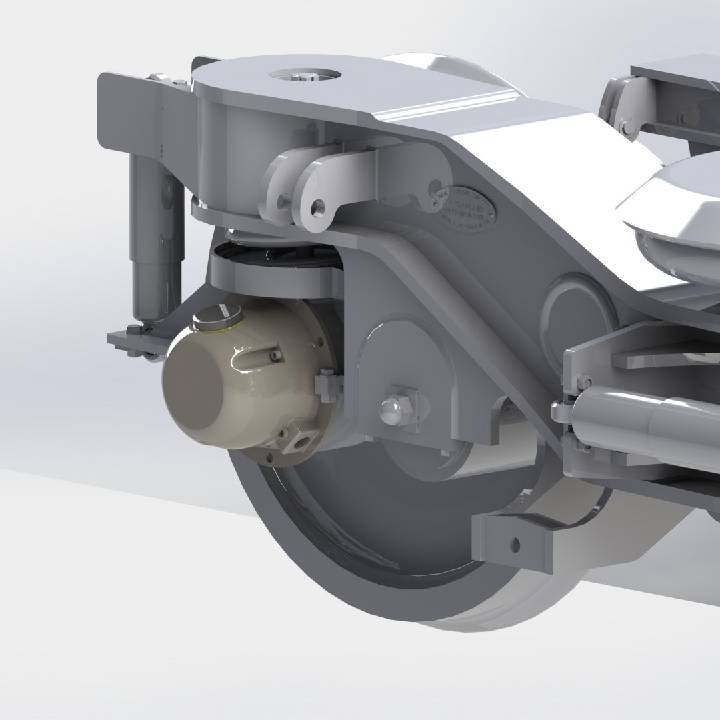

The SAX system applied to the axleboxes of railway bogies is a self-powered system of predictive diagnostics of the rolling stock anomalies and the ground infrastructure on which this rolling stock moves. SAX can detect vibration, temperature, noise, accelerometer, gyroscopy, inclinometry, altitude, distance and speed travelled, satellite localization, and wireless communication signals.

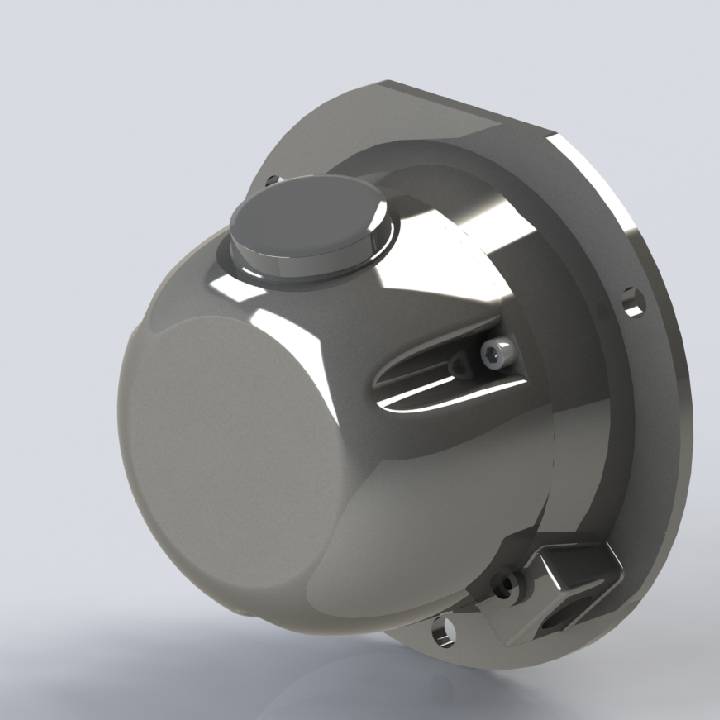

It is a lid-shaped device, applicable directly to the ends of the bushings. The device has an innovative power supply logic using an internal battery, which is recharged by exploiting the kinetic energy produced by the rotation of the wheels.

Predicts anomaly parameters through proprietary and patented data analysis algorithms

SYPLA SAX - MAIN SOLUTION BENEFITS & KEY FEATURES

- Integrated intelligent diagnostic monitoring system of rolling stock axle boxes, vehicle dynamics, and railway infrastructure

- High processing capacity and geolocalized data transmission for the integrated management of predictive maintenance services for rolling stock and infrastructure

- Self-powered, compact and easily installed on the trolley. Can be used for commercial trains, freight trains, constructions vehicles, and diagnostic trains

- Dynamic management of maintenance intervention planning and real time processing of all data produced and transmitted to the ground on a physical server or in the cloud

- Ultra resistant metal materials and easy installation adaptability due to 3D printing production

- Proprietary and patented solution at the European and International level

SAX allows a web-user to access it remotely via a wireless connection. The remote user can monitor the main parameters through an interactive user interface.

The user interface can be reached from any device that has an internet connection and a browser. Furthermore, SAX is geolocated and it is possible to follow its path through the graphical interface.

Technical specifications

- Triaxial acceleration measurement

- Triaxial gyroscopy measurement

- Triaxial inclinometry measurement

- Carriage alignment determination

- Bushing temperature detection

- Bush acoustic detection

- Vehicle dynamics monitoring

- Wheel anomaly diagnostics

- Diagnostics of wheel-rail interaction anomalies

- Rail diagnostics

- Binary diagnostics

- Relative / absolute distance travelled measurement

- Instant speed measurement

- GPS/INS/IMU localization

- Wi-Fi and GSM-LTE-4/5G data transmission

- Self-diagnosis

- Self-feeding

- Rotational energy storage

- Operating temperature range -40/85°C

Customer stories

Alcuni dei clienti che hanno implementato la nostra piattaforma tecnologica

Contact – Production Group Srl

Installazione di SYPLA Industry 4.0

Gruppo FS e RFI – Prog. S.I.M.BA.S.

Installazione di SYPLA Rail

Gasparoli Spa

Installazione di SYPLA Building